Endeavos Innovations Inc. is a comprehensive product development, research, and engineering services consultancy company.

Our core philosophy is based on close collaboration with

startups, academia, and established companies to help innovation through engineering.

State-of-the-art methods and tools are combined with years of experience to move an initial idea through various phases of technology development to market in the least amount of time and cost.

Our services can also be employed at any phase of development or for any engineering or consulting need.

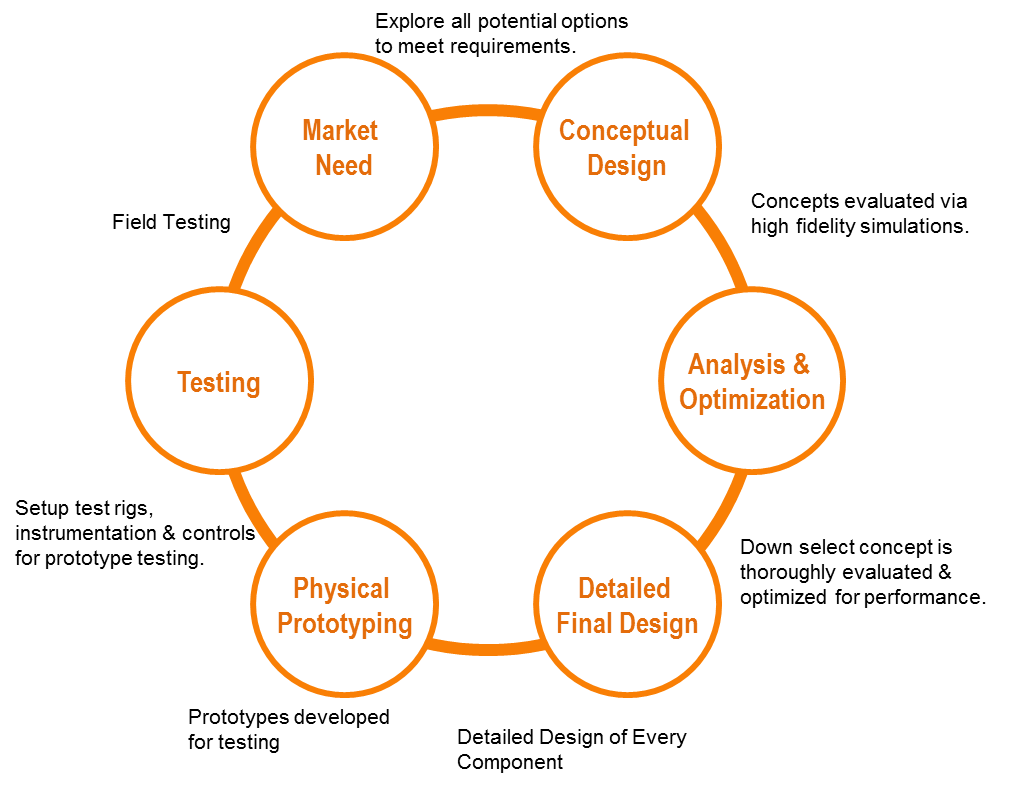

We add value to our client’s business throughout the Product Development Process as shown below:

Close Collaboration

Product development is a highly nonlinear and iterative process. It requires constant communication and feedback from the end-user. We believe in working closely with our client to mitigate risks at each phase of the technology development process.

Lean Product development

Our approach is to iterate through Design-Build-Test-Validate loop in rapid succession. The last step “customer or end-user validation” is the key to preventing over-engineering or relying on assumptions. This enables the product development process to be completed on schedule and within budget.

Conceptual Design Phase

By spending more time in the initial phase of the Product Development Process, we are able to fully explore all potential solutions. Innovation benefits tremendously during the conceptual phase if lots of ideas are generated and tested quickly, in particular, ideas coming from diverse backgrounds. We bring our own unique expertise to the table in order to carry out effective brainstorming.

Concepts generated at this stage are evaluated mainly for end-user functionality, manufacturability and regulatory requirements. All intellectual property developed during the course of the project is transferred to the client.

Engineering Services

We are a one-stop resource for all engineering services throughout the course of your project: from concept generation to detailed design and simulations to physical prototyping and testing. We constantly strive to stay on top of the latest methods and tools available in the industry. If we lack expertise or resource, we will work with our partners to get the task done. This saves our client valuable time and money.

Material & Process Selection

We use material selection and DFMA (Design For Manufacturing & Assembly) methods in the initial phase of the project. This helps in establishing manufacturer, manufacturing process and cost models early. Therefore, subsequent technology development and computational work are tightly integrated with manufacturing and cost model. This saves valuable project time and money later on in the development process.

Technology Transfer

We help establish best practice and methods specific to our client organization. This includes simulation test cases combined with physical testing and detailed technical documentation. We can also provide custom training in specific technology areas including software tools.

Technical Documentation

We provide technical documentation including reports and presentations at every phase of the project. This is one of the most valuable assets a company can have.

Reduced Overhead Costs

We provide expertise & resource when needed by our clients. For this, we will also work on-site if required. This means lower overhead cost and rapid time-to-market for startup companies and valuable additional resources on standby for large organizations.