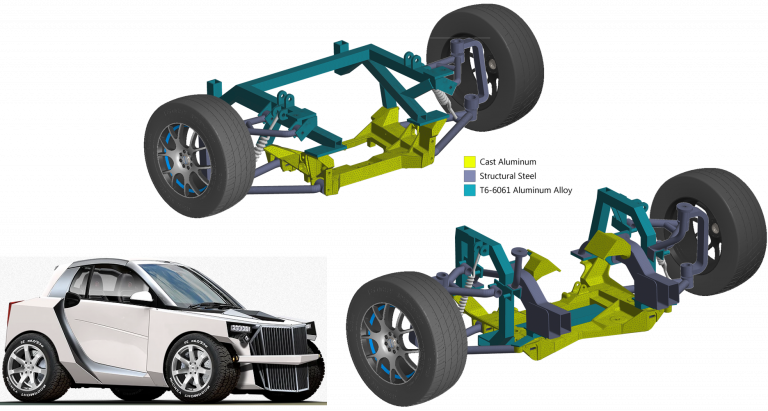

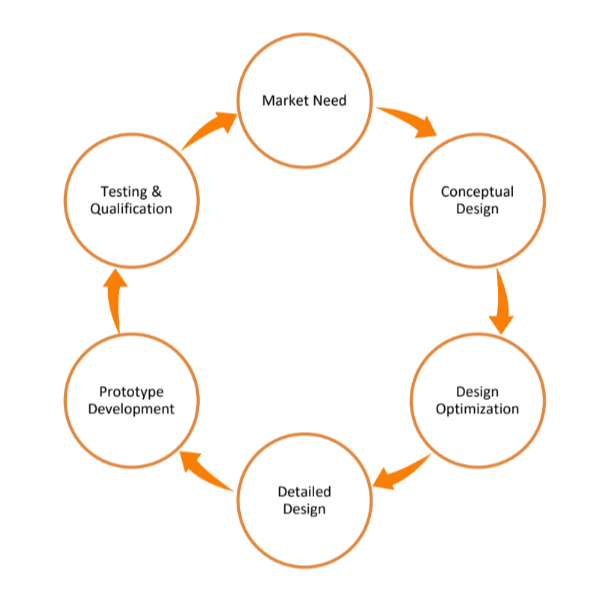

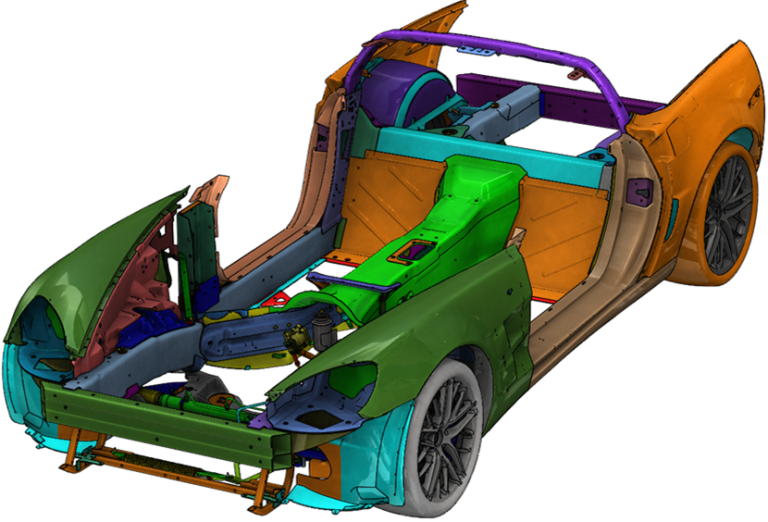

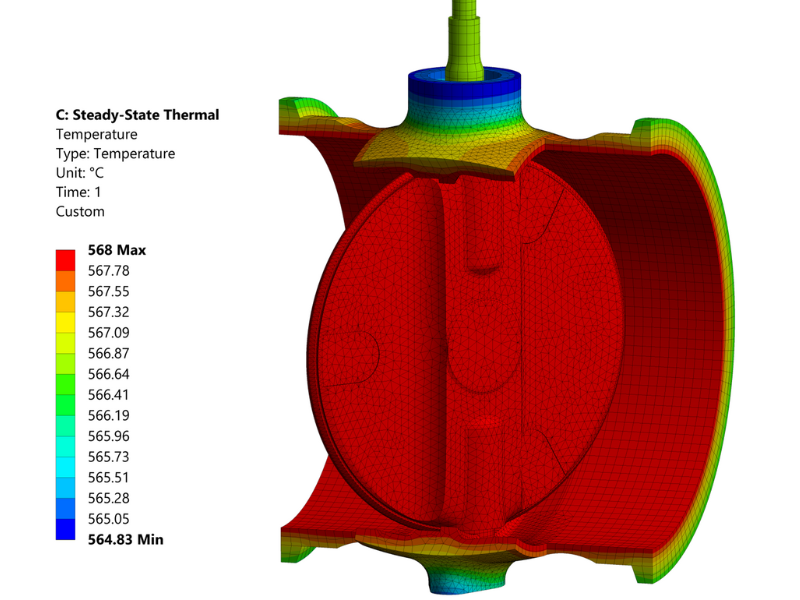

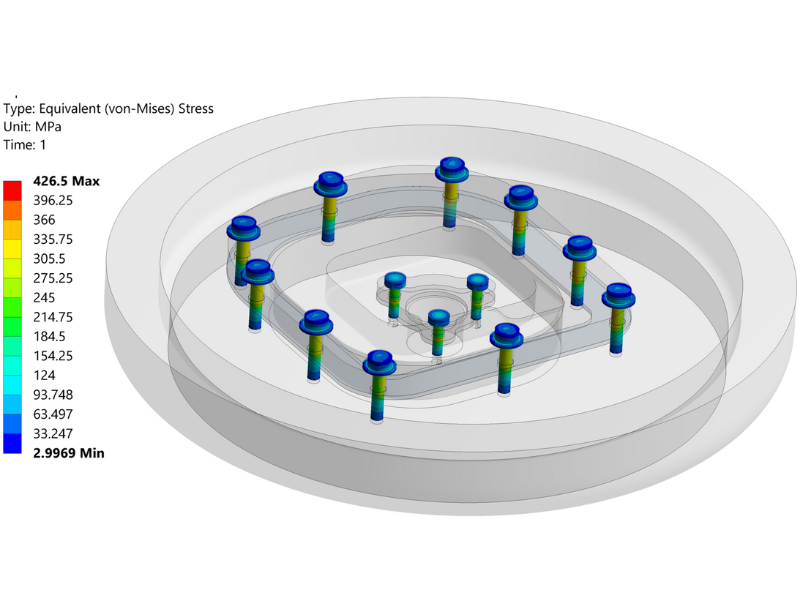

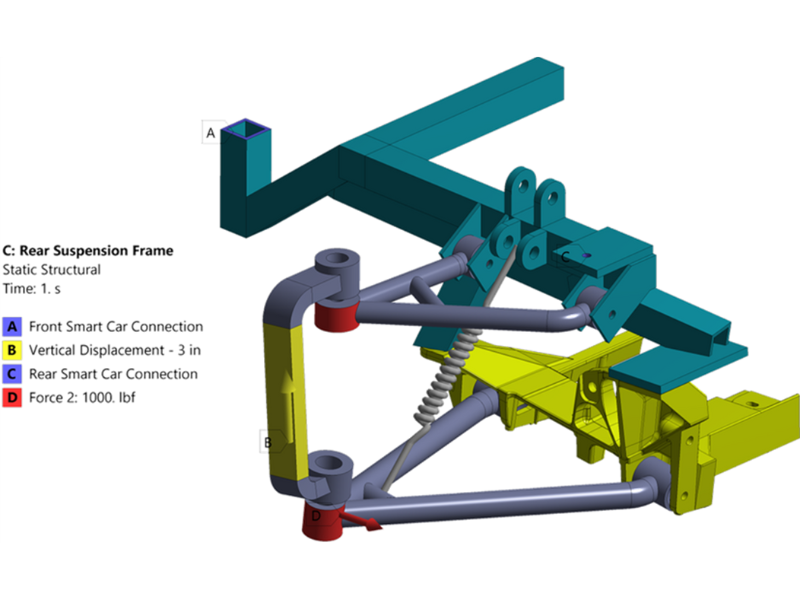

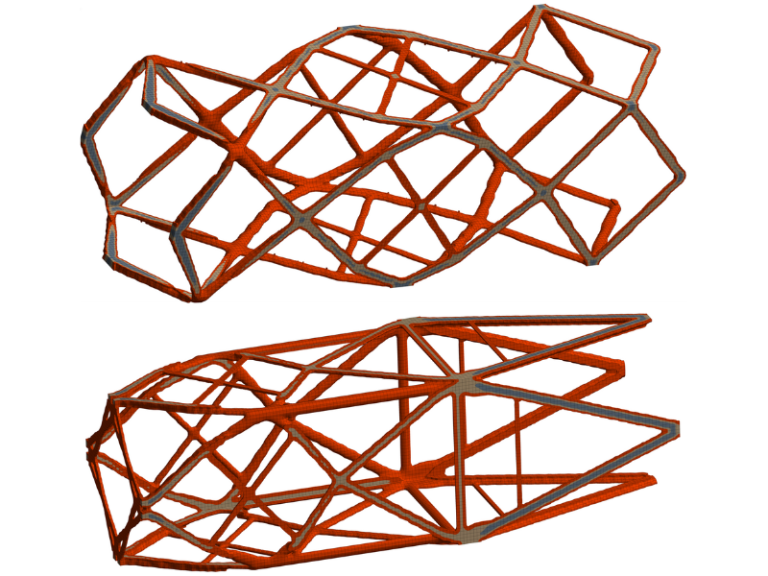

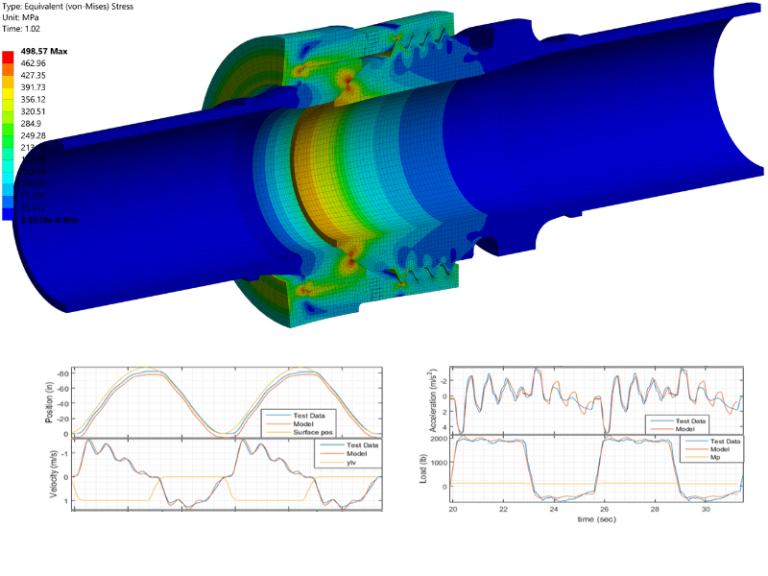

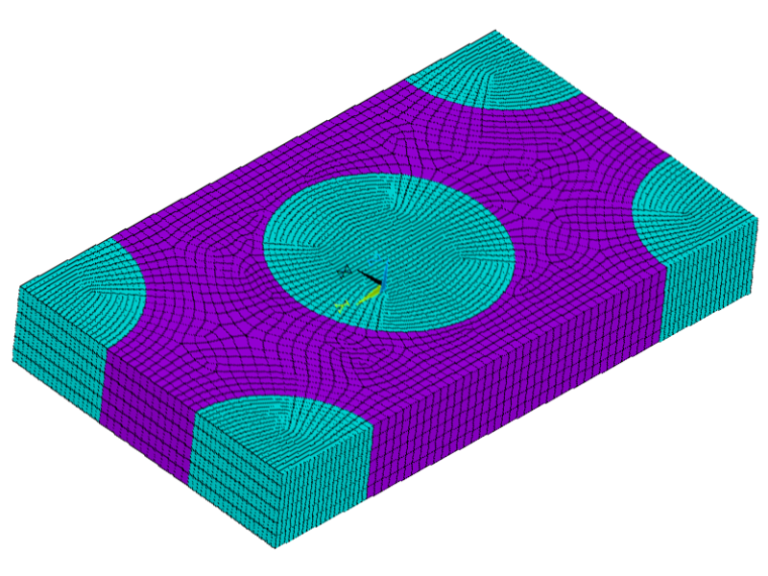

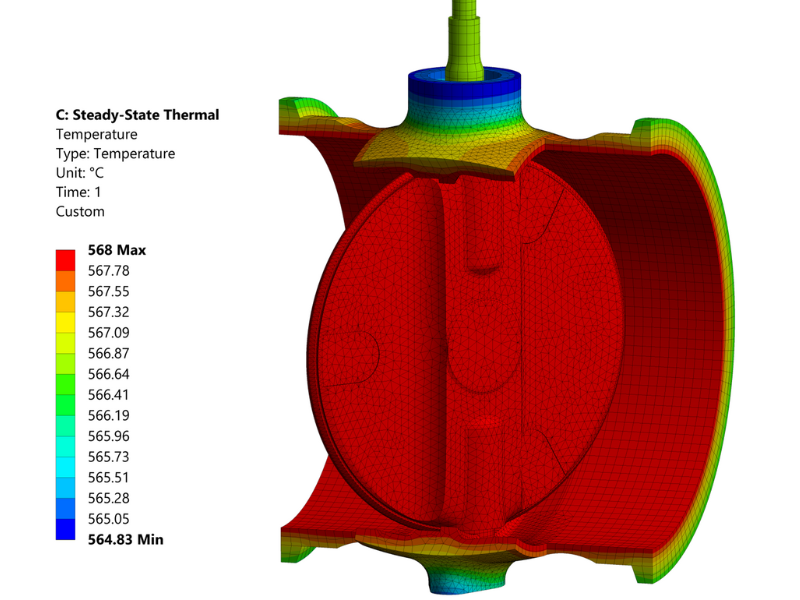

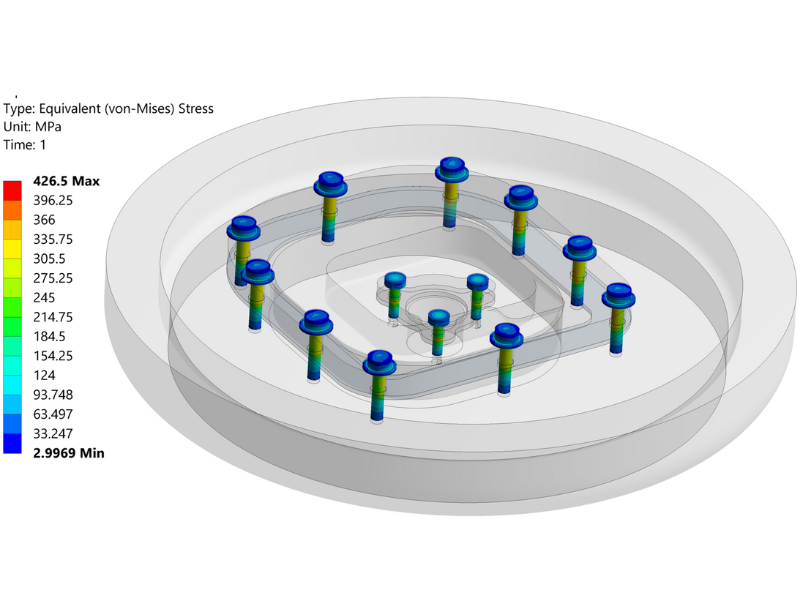

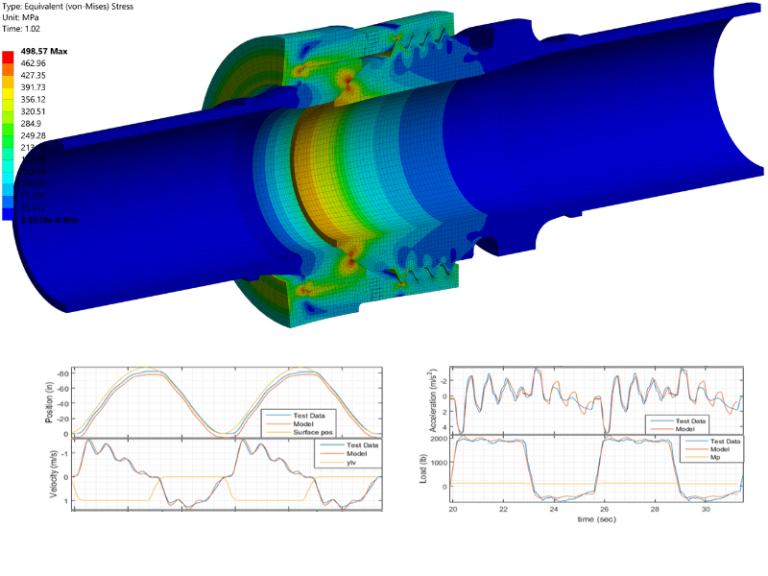

We specialize in Thermal-Structural finite element analysis (FEA), offering expertise in evaluating both existing market products and new product development—from concept to prototyping and testing.

Our mission is to facilitate rapid progress for our clients through dependable simulation-driven design and analysis.

In our initial consultation, we evaluate your analysis needs in the context of your business or R&D objectives and provide strategic advice. Don’t hesitate to contact us for your complimentary consultation.

In some cases, FEA might not be the right approach.

Every analysis is focused on achieving desired objectives to enable rapid progression of the overall project.

We value the desired outcome, not the analysis.

* All FEA models are verified by analytical formulation (if available) or simple hand calculations.

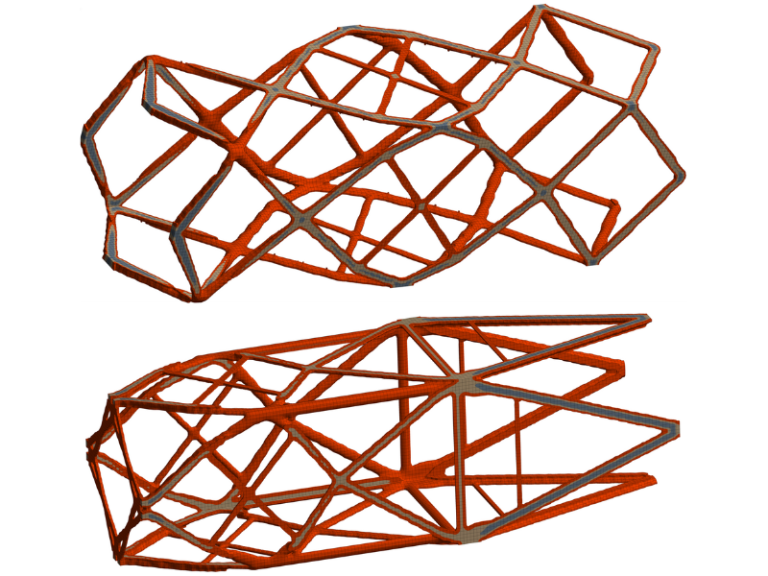

Ideal For: De-risking early-stage concepts before committing to costly prototypes. Feasibility studies, concept development, and validation.

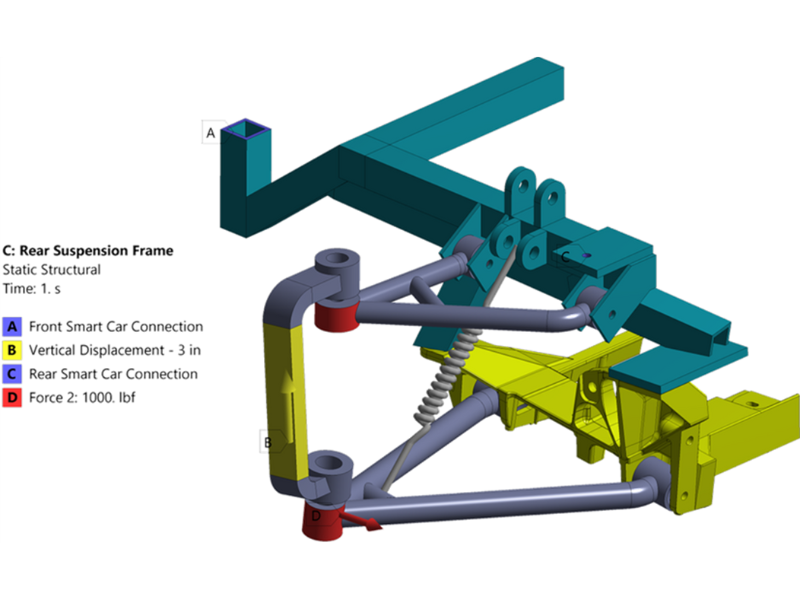

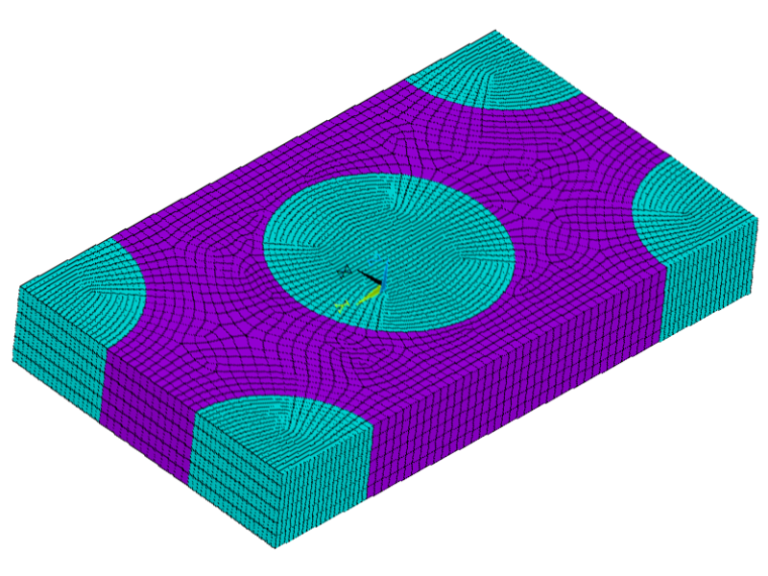

Ideal For: Detailed design analysis & performance optimization of components & assemblies before prototype fabrication.

Ideal For: Recurring needs such as FEA, design checks, analysis reviews, and consulting. Minimum 3-month contract, cancel or pause anytime after that.

Ideal For: Ongoing projects requiring continuous FEA support on multiple models from concept development & optimization to prototyping & testing, technical reviews, custom FE macros & analysis tools customized to the client’s needs. Minimum 3-month contract, cancel or pause anytime after that.

Imagine, a world where product engineering is reduced to pressing a button. The design is based on experience, and analysis is performed instantaneously. Imagine the benefits of faster time to market with reliable engineering and minimal engineering costs.

While we are not there yet, our mission at Endeavos Innovations Inc. is to achieve this goal by utilizing a comprehensive suite of templates, libraries, and macros that automate workflow and eliminate errors. Utilizing this unique system enables us to deliver faster and more reliably, which translates into lower analysis costs and faster project delivery.

Endeavos Innovations Inc.

453 Kinns Road, Clifton Park, NY 12065, USA

Phone: (518) 312-1466

Email: zaeem@endeavos.com